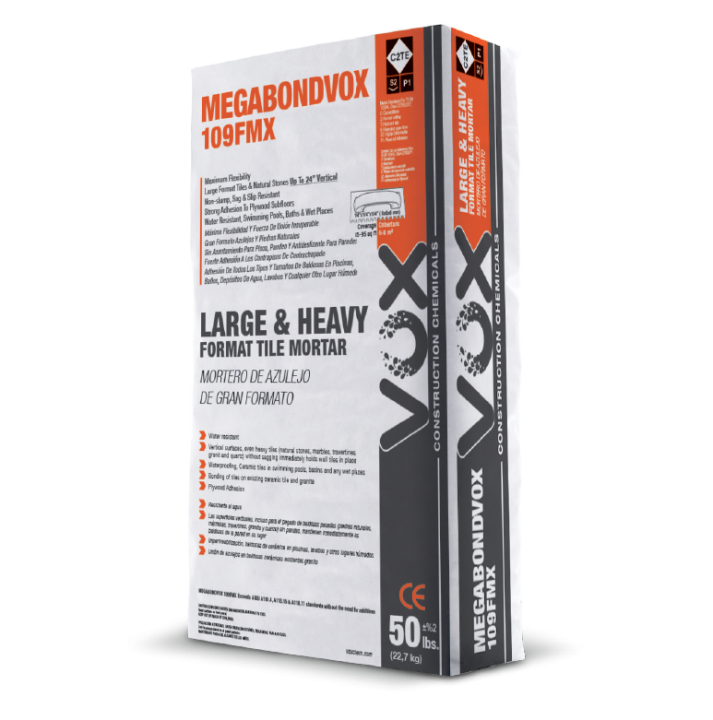

Megabondvox 109FMX

LARGE & HEAVY FORMAT TILE MORTAR

MEETS STANDARDS FOR TS EN 12004, Class C2TES2P1

Maximum Flexibility

Large Format Tiles & Natural Stones Up To 24” Vertical

Non-slump, Sag & Slip Resistant

Strong Adhesion To Plywood Subfloors

Water Resistant, Swimming Pools, Baths & Wet Places

MEGABONDVOX 109FMX Large Format Tile Mortar C2TES2P1

A premium quality, Polymer-modified water resistant MEGABONDVOX 109FMX mortar for any size natural stone or large format ceramic or porcelain tile 24” (60 cm) or larger on one or more sides, other thin or medium bed applications. With a non-slumping formula that reduces the chance for lippage & promotes level tile installations, MEGABONDVOX 109FMX can be applied for vertical and horizontal applications as thick as 3/4” (19 mm) or for thin bed applications to 1/4” (6 mm).

MEGABONDVOX 109FMX Exceeds ANSI A118.4, A118.15 and A118.11 standards without the need for additives

Vertical surfaces, even for bonding of heavy tiles (natural stones,marbles,travertines,granit and quartz) without sagging immediately holds wall tiles in place.

Waterproofing, Ceramic tiles in swimming pools, basins & any wet places.

Bonding of tiles on existing ceramic tile and granite

Plywood Adhesion on horizontal surfaces.

Excellent for glass tile and radiant heating system installations

Supports large any natural stone and heavy tile for flat, even floor installations

MegaBondVox 109FMX can be used for interior or exterior installations, including floors, countertops, walls, ceilings, wet surfaces, bathroom, kitchen, showers, fountains and pools.

Extended open time and reduced slip.

Surfaces treated with Surface GripVox Primer 333P.

Composition of Product

MEGABONDVOX 109FMX Mortar is a dry, proprietary blend of Portland cement, copolymers, inorganic aggregates and chemicals.

Limitations to the Product

Do not bond directly to hardwood, Luan plywood, particle board, parquet, cushion or sponge-back vinyl flooring, metal, fiberglass, plastic or OSB panels. Not recommended for interior and exterior pools and water features. Do not use to install resin-backed stone.

Surfaces to be tiled must be structurally sound and subject to deflection not to exceed the current ANSI Standards.

Plywood floors, including those under resilient flooring, must be structurally sound and must meet all ANSI A108.01 Part 3.4 requirements. Maximum allowable deflection: L/360 tile L/720 stone. See TCNA F150-13 Tile Installations, TCNA F141-13 and F250-13 for Stone.

Applicable Standards

American National Standards Institute (ANSI) -ANSI A108.5, A118.4,A118.15 and A118.11 of the American National Standards for the Installation of Ceramic Tile ASTM International (ASTM)

| Property Propiedad |

Test Method Metodo de Prueba |

Requirement Requisite |

Typical Results Resultados Tipicos |

|---|---|---|---|

| Pot Life | 2 Hours | ||

| Open Time | A118.15 Section 5.3 | E=30 minutes | Pass and Exceed |

| 4 Week Shear Bond Strength / Resistencia de Unión al Cizallamiento de 4 semanas | |||

|---|---|---|---|

| Glazed Wall Tile | A118.15 Section 7.1.2 | > 450 psi | 500-600 psi (35.2 42.2 kg/cm²) |

| Porcelain Tile | A118.15 Section 7.2.5 | > 400 psi | 400 – 500 psi (28.1 35.2 kg/cm²) |

| Quarry Tile to Plywood | A118.11 Section 4.1.2 | > 150 psi | 200 – 300 psi (14.1 21.1 kg/cm²) |

| Sag on Walls | A118.15 Section 6.0 | < 0.02 mm | Pass and Exceed |

| Tile Size Tamaño Del Azulejo |

Typical Trowel Paleta |

Coverage Cobertura |

|

|---|---|---|---|

| < 25 cm2 (<0.02 sq. ft.) | 3 mm-1/8″ |  |

7.00-8.00 m2-75 to 99 sq. ft. |

| 25-100 cm2 (0.02-0.1 sq. ft.) | 4 mm-5/32″ |  |

6.00-7.25 m2-60 to 80 sq. ft. |

| 100-400 cm2 (0.1-0.5 sq. ft.) | 6 mm-1/4″ |  |

4.50-6.25 m2-45 to 65 sq. ft. |

| 400-1600 cm2 (0.5-1.5 sq. ft.) | 8 mm-5/16″ |  |

4.00-5.25 m2-40 to 45 sq. ft. |

| >1600 cm2 (>1.5 sq. ft.) | 10 mm-1/2″ |  |

3.00-4.80 m2-30 to 45 sq. ft. |

TR

TR  ENG

ENG