Techvox 103X

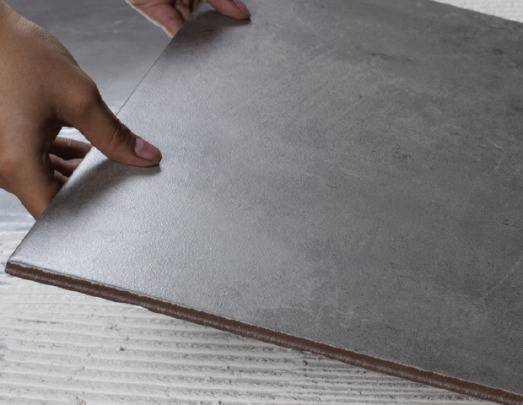

ULTRA PREMIUM POLYMER-MODIFIED THIN-SET MORTAR

TECHVOX 103X Thin-Set Mortar C1TE

A polymer-modified professional formula, all-purpose mortar, to provide good bond strength for floor and tile projects. TECHVOX 103X cures quickly and adheres to most surfaces.

TECHVOX meets and exceeds ANSI A118.4 and A118.11 without the need for additives.

All-purpose mortar.

Extended open time and reduced slip.

Cures quickly even in cold climates.

Vitreous, semi-vitreous or non-vitreous tile: ceramic, mosaic, quarry, cement body tile Impervious porcelain and glass tile.

Brick and thin brick. Cement-based precast terrazzo.

Natural stone tile.

Concrete, mortar beds, masonry, Portland cement plaster.

Surfaces treated with Surface GripVox Primer 333P.

Fully-bonded sheet vinyl flooring (scarified).

Concrete, mortar beds, masonry, Portland cement plaster.

Exterior Grade Plywood (interior residential and light commercial dry areas).

Gypsum wallboard (interior dry areas).

Existing ceramic tile (scarified).

Plastic laminates (scarified).

Cutback adhesive.

Composition of Product

TECHVOX 103X Thin-Set Mortar is a dry, proprietary blend of Portland cement, copolymers, inorganic aggregates and chemicals.

Limitations to the Product

Do not bond directly to hardwood, Luan plywood, particle board, parquet, cushion or sponge-back vinyl flooring, metal, fiberglass, plastic or OSB panels. Not recommended for interior and exterior pools and water features. Do not use to install resin-backed stone.

Surfaces to be tiled must be structurally sound and subject to deflection not to exceed the current ANSI Standards.

Plywood floors, including those under resilient flooring, must be structurally sound and must meet all ANSI A108.01 Part 3.4 requirements. Maximum allowable deflection: L/360 tile L/720 stone. See TCNA F150-13 Tile Installations, TCNA F141-13 and F250-13 for Stone.

Applicable Standards

American National Standards Institute (ANSI) — ANSI A108.5, A118.4 and A118.11 of the American National Standards for the Installation of Ceramic Tile ASTM International (ASTM)

| Property / Propiedad | Test Method / Metodo de Prueba | Requirement/Requisite | Typical Results / Resultados Tipicos |

|---|---|---|---|

| Pot Life | 4 Hours | ||

| Open Time | A118.4 Section 5.3 | > 20 minutes | Pass and Exceed |

| 4 Week Shear Bond Strength / Resistencia de Unión al Cizallamiento de 4 semanas | |||

| Glazed Wall Tile | A118.4 Section 5.1.5 | > 300 psi | 450-550 psi (31.6 38.7 kg/cm²) |

| Porcelain Tile | A118.4 Section 5.2.4 | > 200 psi | 300-400 psi (21.1 28.1 kg/cm²) |

| Quarry Tile to Plywood | A118.11 Section 4.1.2 | > 150 psi | 150-250 psi (10.5 17.6 kg/cm²) |

| Tile Size Tamaño Del Azulejo |

Typical Trowel Paleta |

Coverage Cobertura |

|

|---|---|---|---|

| < 25 cm2 (<0.02 sq. ft.) | 3 mm-1/8″ |  |

7.00-8.00 m2-75 to 99 sq. ft. |

| 25-100 cm2 (0.02-0.1 sq. ft.) | 4 mm-5/32″ |  |

6.00-7.25 m2-60 to 80 sq. ft. |

| 100-400 cm2 (0.1-0.5 sq. ft.) | 6 mm-1/4″ |  |

4.50-6.25 m2-45 to 65 sq. ft. |

| 400-1600 cm2 (0.5-1.5 sq. ft.) | 8 mm-5/16″ |  |

4.00-5.25 m2-40 to 45 sq. ft. |

| >1600 cm2 (>1.5 sq. ft.) | 10 mm-1/2″ |  |

3.00-4.80 m2-30 to 45 sq. ft. |

TR

TR  ENG

ENG